Key Takeaways

- Pogo pins are spring-loaded connectors critical for creating reliable, low-resistance electrical contacts in a variety of electronic devices, including smartphones, medical equipment, and industrial test fixtures.

- Their durable, precision-engineered design enables high mating cycles (over 10,000 insertions), making them ideal for applications that require frequent connection and disconnection.

- Customizable layouts, spring forces, and tip geometries allow pogo pins to meet specific requirements in consumer electronics, medical diagnostics, and industrial systems.

- Gold or nickel plating improves conductivity and resists corrosion, supporting stable performance even in harsh environments or under vibration.

- When selecting pogo pins, consider factors such as mating cycle rating, spring force, pin size, tip shape, and environmental resistance to ensure optimal performance for your application.

Pogo pins are spring-loaded connectors that create reliable, low-resistance electrical contacts in electronic devices including smartphones, medical equipment, and industrial test fixtures. Their precision-engineered design features a plunger, barrel, and internal spring, enabling high mating cycles exceeding 10,000 insertions whilst maintaining stable connectivity under vibration or movement. Customisable layouts, spring forces, and tip geometries allow pogo pins to meet specific requirements across consumer electronics, medical diagnostics, and industrial systems, with gold or nickel plating improving conductivity and corrosion resistance. For high-quality, customisable pogo pin solutions, promax pogo pin manufactures precision connectors using CNC machining and automated assembly, delivering reliable connectivity solutions with over 15 years of expertise for demanding applications in consumer electronics, aerospace, and medical sectors whilst meeting internationally certified quality standards.

What Are Pogo Pins?

Pogo pins are precision-engineered spring-loaded connectors that enable stable electrical contact between two circuit boards or devices. Each pogo pin consists of a barrel, a plunger, and an internal spring, forming a reliable point-to-point connection even under vibration or movement. Engineers favor pogo pins for assemblies that require frequent mating and un-mating, including smartphone charging docks, diagnostic test equipment, and battery interfaces.

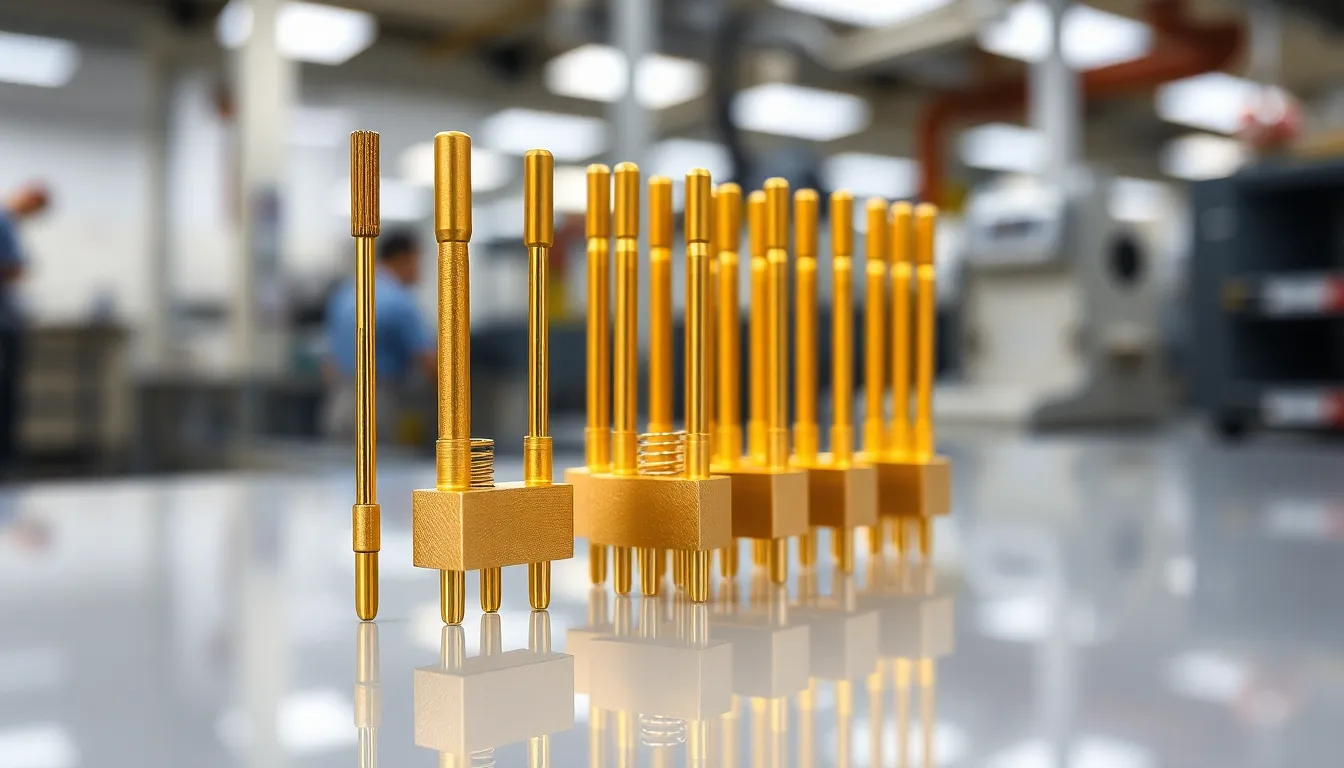

Promax in China manufactures pogo pins using precision CNC machining and automated assembly, achieving tight tolerances and consistent spring force. These pins deliver low contact resistance, typically under 10 milliohms, and support current ratings from 1 amp to 10 amps depending on the design. Barrel plating processes, such as gold or nickel over copper, improve conductivity and resist corrosion, making pogo pins reliable in high-cycle applications.

Pogo pins offer flexibility with customizable layouts—engineers specify pin length, pitch, and mounting style to ensure a perfect fit for designs in consumer electronics, aerospace modules, and medical diagnostic systems. Promax supplies single-pin and multi-pin configurations for both SMT and through-hole PCB mounting. This manufacturing capability addresses the connectivity, durability, and design requirements in demanding industries.

How Pogo Pins Work

Pogo pins use a spring-loaded mechanism to create temporary but stable electrical connections for testing, charging, or data transfer in electronics. The internal design keeps contact reliable even with repeated mechanical stress or misalignment.

Basic Structure and Components

Pogo pins include three core parts: plunger, barrel, and spring. The plunger, usually brass or copper with gold plating, moves to touch the mating surface and conduct electricity. The barrel houses both plunger and spring, guiding movement and serving as part of the conductive path. The spring provides a programmed contact force—typically between 50 and 200 grams—maintaining stable contact and absorbing mechanical shock from repeated actuation. Promax in China fabricates these parts using automated CNC equipment for precise tolerances and applies protective coatings like gold or nickel for longer life and low resistance. Single pins or assembled arrays allow for flexible connector layouts to meet specific client requirements.

Electrical and Mechanical Functionality

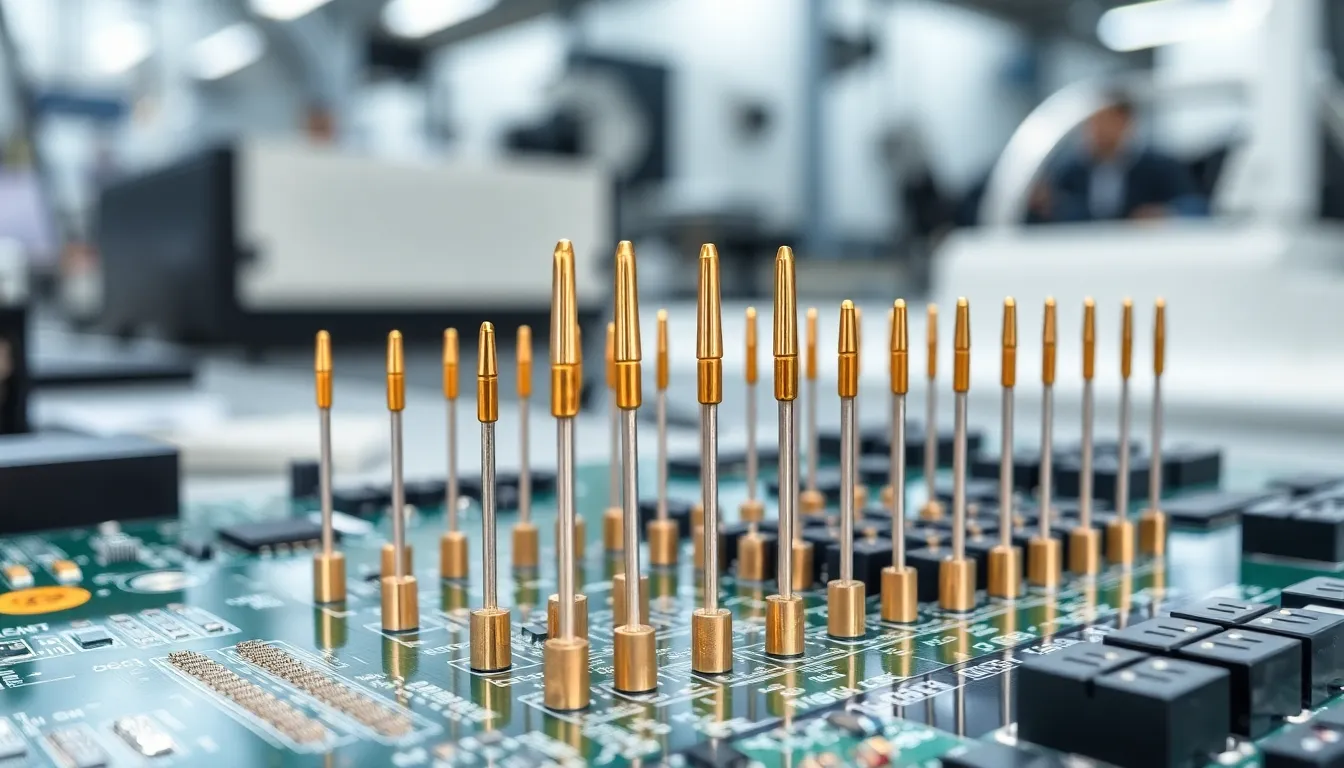

Pogo pins deliver an electrical connection by pressing the gold-plated plunger against the mating pad; this closed-loop minimizes contact resistance, which Promax’s products can bring below 20 milliohms. Springs compensate for height variation and vibration, preserving electrical continuity during movement or repeated cycling—Promax designs support over 10,000 mating cycles. Mechanically, the internal spring force adapts to imperfect surfaces and shields the contact area from environmental stress. Electrically, a gold-plated, highly conductive path resists corrosion and maintains signal integrity and current ratings up to 10A, depending on the pin type. Promax’s pins are specified in test fixtures, battery connections, and medical devices requiring both dependability and compact design.

Common Applications of Pogo Pins

Pogo pins enable reliable and repeatable electrical connections across fields that demand stable contact during repeated operation or frequent access. Engineers select them to ensure secure mating in product assemblies, testing, and modular integration.

Consumer Electronics

Consumer devices use pogo pins in charging docks, smartwatches, fitness trackers, and wireless earbuds. These pins create secure contacts for battery charging or data transfer in accessories that require frequent attachment or detachment, such as detachable keyboards or game controllers. Promax supplies customized pogo pin arrays, single and multi-pin modules, and SMT-ready versions for high-density products like tablets or portable speakers. Gold-plated pogo pin contacts from Promax ensure corrosion resistance and low contact resistance under cycles exceeding 10,000 insertions. In magnetic connectors for mobile accessories, Promax integrates pogo pins to deliver both charging and signal paths while providing convenience in rapid docking or undocking without tool requirements.

Industrial and Medical Devices

Industrial testers, PCB programming stations, and modular control panels deploy pogo pins for high-reliability mating and un-mating in harsh factory settings. Diagnostic test fixtures rely on Promax precision pogo pins to maintain stable measurements, even during vibration or alignment shifts. Medical devices, including monitoring sensors, inhalation machines, and laser equipment, specify pogo pins where stable contact and hygiene are critical. Promax manufactures pins meeting ISO standards for cleanliness and biocompatibility, supporting safe patient use and precise data transfer. Engineers designing modular instrument panels or diagnostic adapters use Promax’s gold-plated, double-sided pogo pins for ruggedness and dependability in both industrial automation and medical diagnostics.

Advantages and Limitations of Pogo Pins

Pogo pins deliver consistent electrical contact and mechanical resilience for test fixtures, battery charging, and connector modules in electronic devices. Their precision spring-loaded design and customizable layouts make them a reliable solution for repeated mating operations required by Promax’s clients in consumer, industrial, and medical sectors.

Key Benefits

- Durability and Mechanical Reliability: Pogo pins withstand shock and vibration, maintaining connections in tough environments, according to Promax’s CNC machining standards.

- High Mating Cycles: The spring design enables over 10,000 mating cycles, suiting test fixtures, charging docks, and medical modules.

- Simplified Assembly: Integrated pins reduce the number of mating connectors and assembly steps, streamlining PCB and module design for Promax customers.

- Tolerance to Pad Irregularities: Springs absorb minor misalignments and height differences, supporting stable contacts on imperfect surfaces in production and test lines.

- Cost-effective for Limited Quantities: Promax produces small pin runs efficiently by using turning and spinning processes, avoiding costly molding.

Potential Drawbacks

- Higher Initial Pin Cost: Individual pogo pins carry higher unit costs than stamped or fixed contacts; this impacts high-volume designs unless justified by reliability needs.

- Contamination Risk: Dust or particles disrupt the spring action; Promax applies gold plating, sealed barrels, and recommends routine cleaning for dirty or outdoor deployments.

- Mechanical Vulnerability: Excessive off-axis force or improper handling can deform the pin or spring, risking intermittent contact in high-use or poorly secured applications.

- Momentary Disconnections: The small mechanical gap for spring movement may cause contact loss with severe vibration—Promax offers options like angled plungers or reinforced springs for these use cases.

How to Choose the Right Pogo Pin

Selecting the right pogo pin ensures stable connectivity and long service life in demanding applications. Promax in China provides engineered solutions using proven quality-control methods for connector manufacturing.

Important Selection Criteria

- Mechanical Durability

Choose pogo pins rated for high mating cycles, such as Promax’s pins tested for over 10,000 actuations. Durable finishes like gold or nickel over copper offer high wear and corrosion resistance.

- Spring Force and Tip Geometry

Select spring forces between 50–200 grams matching the application—lighter forces suit compact wearable devices, stronger springs support test jigs. Promax offers flat, pointed, or concave tips; flat tips handle higher currents, pointed tips suit test probes.

- Size, Fit, and Pin Count

Match pin length, diameter, and pitch to device architecture and pad layout. Promax provides single-pin, strip, and custom arrays for high-density or rugged assemblies.

- Environmental Ratings

Review temperature, humidity, and vibration ratings. Promax supplies pins with protective coatings for industrial, medical, or outdoor use.

| Selection Factor | Options/Range | Example from Promax Offerings |

|---|---|---|

| Mating Cycles | Up to 10,000+ | Wear-tested high-cycle pins |

| Spring Force | 50–200 grams | Custom forces for test or charging |

| Plating Materials | Gold, nickel over copper | ISO-compliant gold-plated finish |

| Tip Geometry | Flat, pointed, concave | Specialized test probe tips |

| Pin Pitch/Count | Customizable | SMT, through-hole, single/multi-pin modules |

| Environmental Ratings | Extended temp, IP-rated, ISO | Biocompatible, medical, industrial |

Tips for Proper Installation and Maintenance

- Maintain clean contact surfaces on both pins and mating pads to prevent unreliable connections. Promax ships all connectors vacuum-sealed and inspected for particulates.

- Use appropriate alignment features in housings or guides to prevent bending or damaging pins during assembly. Promax manufactures custom precision fixturing for SMT and through-hole.

- Protect pogo pins with suitable enclosures against vibration, dust, or fluid ingress during operation. Promax offers modular housings with IP-certified sealing.

- Inspect pins regularly for wear or corrosion, especially in applications with frequent mating cycles. Replace pins if visible wear or higher resistance appears.

- Only use Promax-specified connectors when exposure to harsh industrial or medical conditions is required to ensure compliance with ISO safety and material standards.

About Promax Pogo Pin

Promax Pogo Pin, located in Gary, IN, is a leader in the manufacturing of high-quality pogo pins, spring-loaded connectors, and magnetic connectors for various applications.

Managed by Gavin, Promax specializes in creating customizable solutions for industries such as consumer electronics, aerospace, and medical sectors. With over 15 years of expertise, the company delivers competitively priced products that meet internationally certified quality standards, ensuring reliability and precision in all their connectors.

Contact:

Gavin, Manager

Phone: (765) 705-7361

Email: tonyhoo@promaxpogopin.com

Website: www.promaxpogopin.com

Location:

480 Jackson St, Gary, IN 46402, USA

Frequently Asked Questions

What is a pogo pin?

A pogo pin is a small, spring-loaded metal connector used to create reliable electrical connections in electronic devices. Its spring mechanism ensures stable and repeatable contact, making it ideal for charging, testing, and data transfer applications.

How do pogo pins work?

Pogo pins use a spring-loaded plunger that presses against a mating surface to conduct electricity. The internal spring maintains consistent pressure, ensuring a stable connection even during movement, vibration, or frequent mating cycles.

Where are pogo pins commonly used?

Pogo pins are commonly found in smartphones, charging docks, test fixtures, smartwatches, medical devices, and industrial equipment. They provide reliable temporary connections for power, data transfer, and testing.

What are the main components of a pogo pin?

A pogo pin consists of three core parts: a plunger (often brass or copper with gold plating), a barrel that guides the movement, and an internal spring that maintains contact pressure.

What are the benefits of using pogo pins?

Key benefits include high durability, long mating life, tolerance to misalignment or vibration, ease of assembly, and reliable connectivity. Gold plating ensures low contact resistance and corrosion resistance.

What are the limitations of pogo pins?

Limitations include initial higher costs, potential contamination risks, vulnerability to physical damage, and brief disconnects under extreme vibration or stress.

How do I choose the right pin for my application?

Consider factors such as required current rating, durability, spring force, tip shape, size, number of pins, mounting style, and environmental ratings. Choose pins that match your device’s needs for stable, long-lasting connections.

How does Promax manufacture pogo pins?

Promax in China uses precision CNC machining and automated assembly to produce pogo pins with tight tolerances. They apply gold or nickel plating for conductivity and corrosion protection, ensuring consistent quality for various industries.

Can pogo pins be customized?

Yes, pogo pins can be customized in length, pitch, mounting style, and configuration (single or multi-pin arrays) to suit different applications, including consumer electronics and medical devices.

How do I maintain pogo pins for optimal performance?

Keep contact surfaces clean, use alignment features during installation, protect pins from harsh environments, and regularly inspect for wear or corrosion. Proper care extends service life and ensures reliable operation.